News

LatestThe JBT PRoFLEX: changing how homestyle textures are applied

Read Time: 2 min - Looking to take advantage of the growing trend towards homestyle textures for...

Portioning & Slicing

LatestJBT continues to lead through innovation at Anuga FoodTec 2024: a quick recap

Read Time: 5 min - JBT’s presence at Anuga FoodTec 2024 was very successful in terms of showcasing...

Coating, Frying

LatestThe JBT PRoFLEX: changing how homestyle textures are applied

Read Time: 2 min - Looking to take advantage of the growing trend towards homestyle textures for...

Mixing & Grinding

Latest1,000 kilograms of chicken per hour: JBT alco implements mega production line in Southeast Asia

Read Time: 4 min - JBT alco’s Business Development Manager, Thomas Kleine-Ausberg, tells the story...

Primary Processing

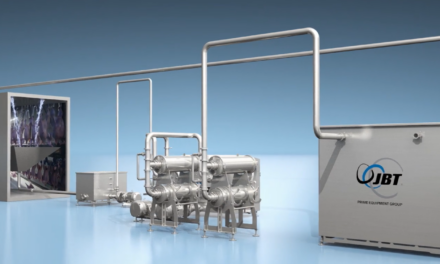

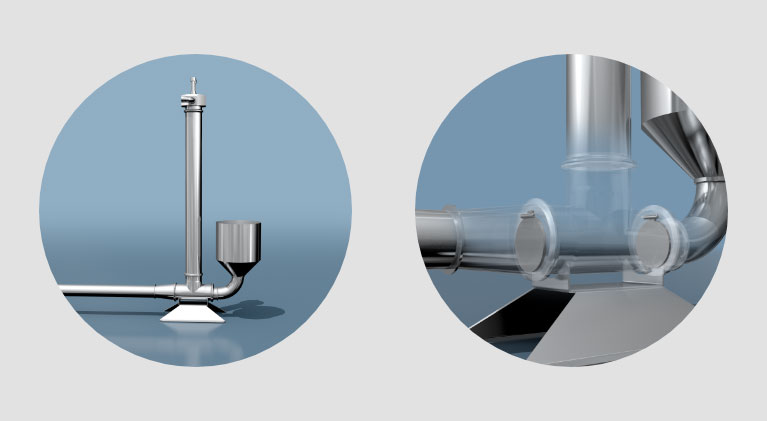

LatestRevolutionizing Water Conservation with JBT’s Prime Water Reuse System

Read Time: 4 min - Water is an essential resource in the poultry processing industry. From...

Freezing & Chilling

LatestJBT continues to lead through innovation at Anuga FoodTec 2024: a quick recap

Read Time: 5 min - JBT’s presence at Anuga FoodTec 2024 was very successful in terms of showcasing...

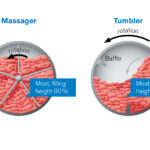

Injection & Marination

LatestNetting profits: why JBT is the best catch for maximizing fish yield and quality

Read Time: 3 min - Demand for fish and seafood is immense and growing, but at the same time fish...

Clipping

LatestJBT continues to lead through innovation at Anuga FoodTec 2024: a quick recap

Read Time: 5 min - JBT’s presence at Anuga FoodTec 2024 was very successful in terms of showcasing...

Weighing

LatestJBT’s VAC CAT: the optimum weight solution for tricky products

Read Time: 2 min - Raw poultry and meat can be among the most challenging products when it comes...

Cooking

PopularAdding flexibility to ready-meal production: the alco HotCook

Looking for a fast, flexible solution for preparing ready-to-eat-products? JBT alco’s HotCook AHC is a multifunctional system for searing, simmering and cooking, which offers flexibility and variability.

Forming

Latest1,000 kilograms of chicken per hour: JBT alco implements mega production line in Southeast Asia

Read Time: 4 min - JBT alco’s Business Development Manager, Thomas Kleine-Ausberg, tells the story...

X-Ray Food Inspection

LatestNetting profits: why JBT is the best catch for maximizing fish yield and quality

Read Time: 3 min - Demand for fish and seafood is immense and growing, but at the same time fish...

Sustainability

LatestJBT alco: making a sustainable difference for the holiday season

Read Time: 2 min - JBT alco has announced plans to make a sustainable difference this holiday...